Custom made Resin Coated Sand Solutions

What makes AMM a favoured choice for it clients and customers is its ability to provide customisable and favourable technical solutions, keeping in mind the issues & the challenges faced by organisations and companies.

In today’s day & age, foundries have been facing immense issues & problems with castings, which needs to be addressed with sincerity & urgency. We can say this with utmost surety that AMM has been providing doable solutions to foundries & it’s customers. AMM Resin Coated Sand is being continuously developed and improved, with a goal of achieving 0% defects in castings.

While most Indian manufacturers use liquid resin and semi-hot method of mixing, AMM uses solid phenolic resin, developed by AYC Japan, and dry-hot way of mixing. This enables AMM to offer resin coated sand with better heat resistance, higher strength & lower gas evolution.

Unlike other Indian manufacturers who simply increase or decrease the percentage of resin in the product, AMM uses different kinds of solid phenolic resins developed by AYC Japan.

AMM’s resin coated sand is being continuously developed and improved for zero defects in castings. Some of the problems faced by Indian casting manufacturers are:

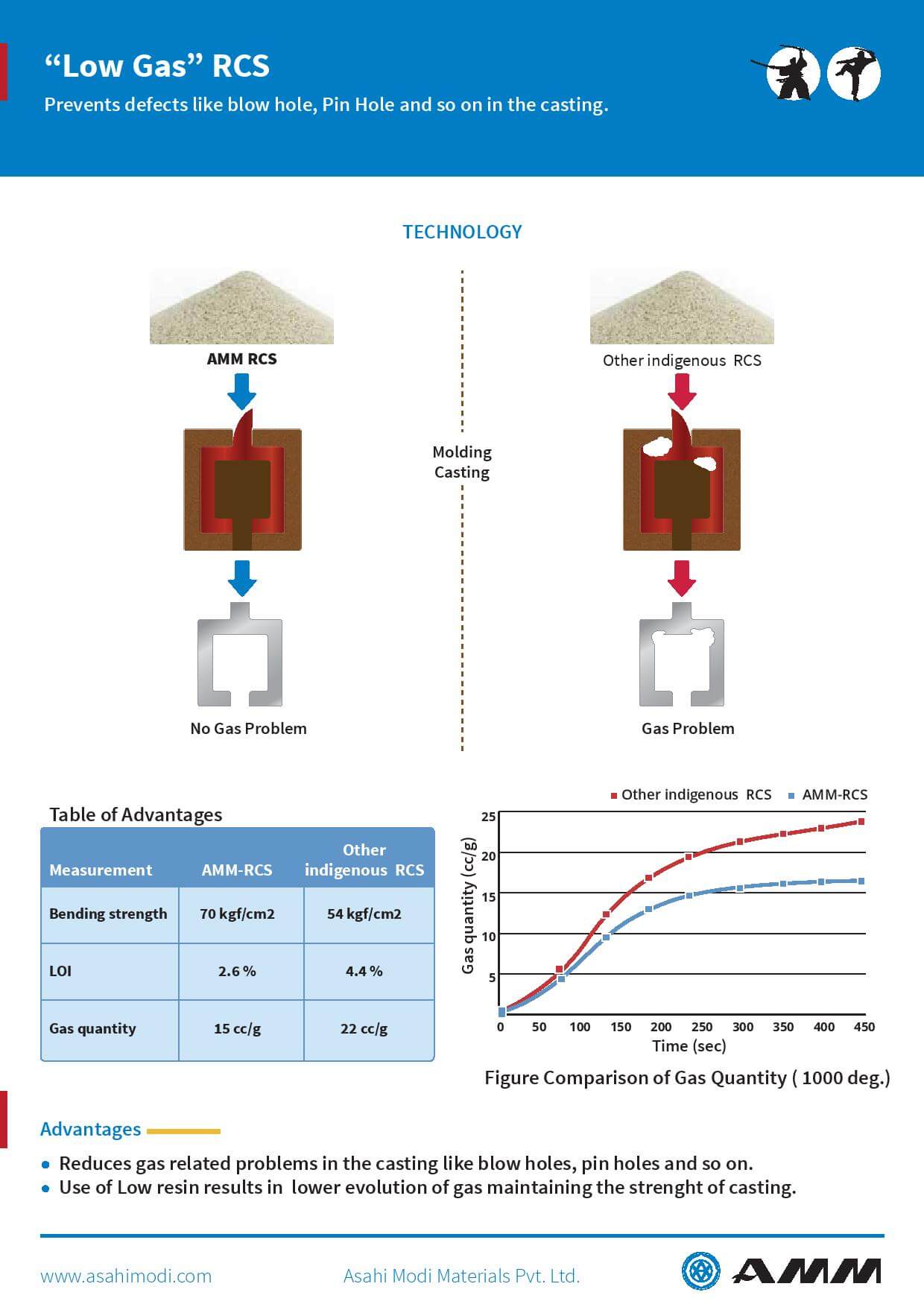

- Gas defects (Pin hole, blow holes)

- Surface finish

- Veining

- Core/mold unfilling

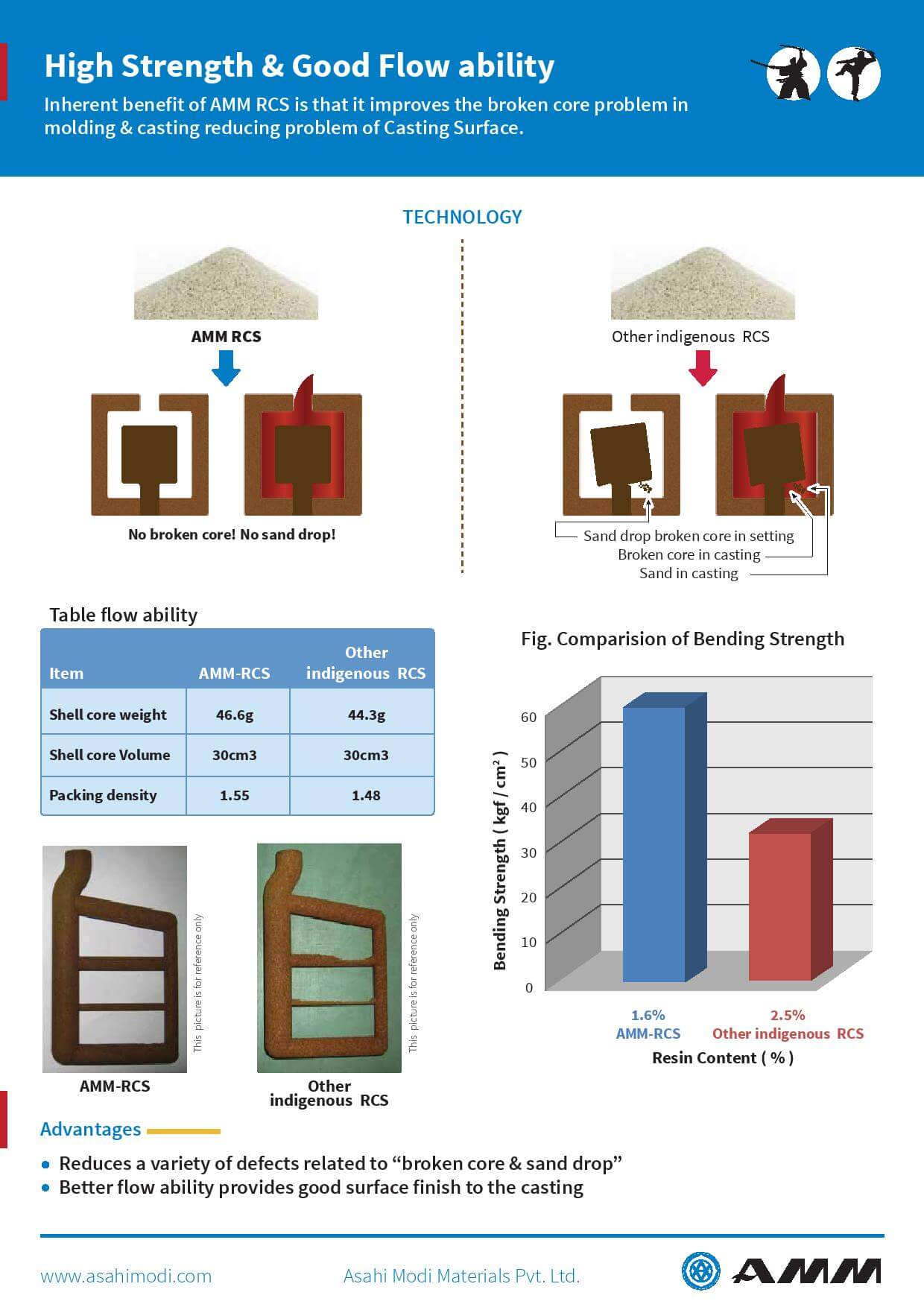

- Core-mold breakage due to low strength

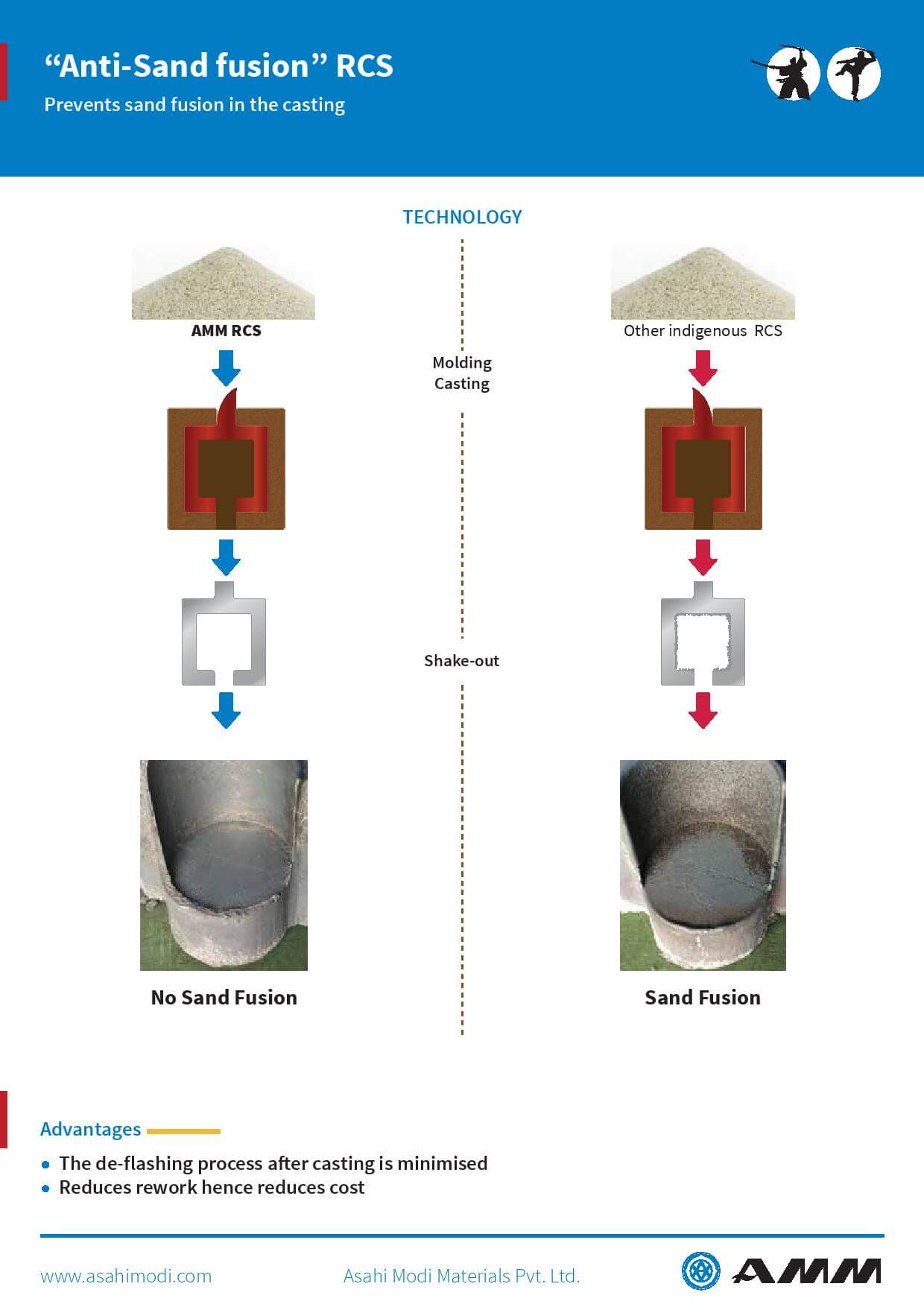

- Sand fusion

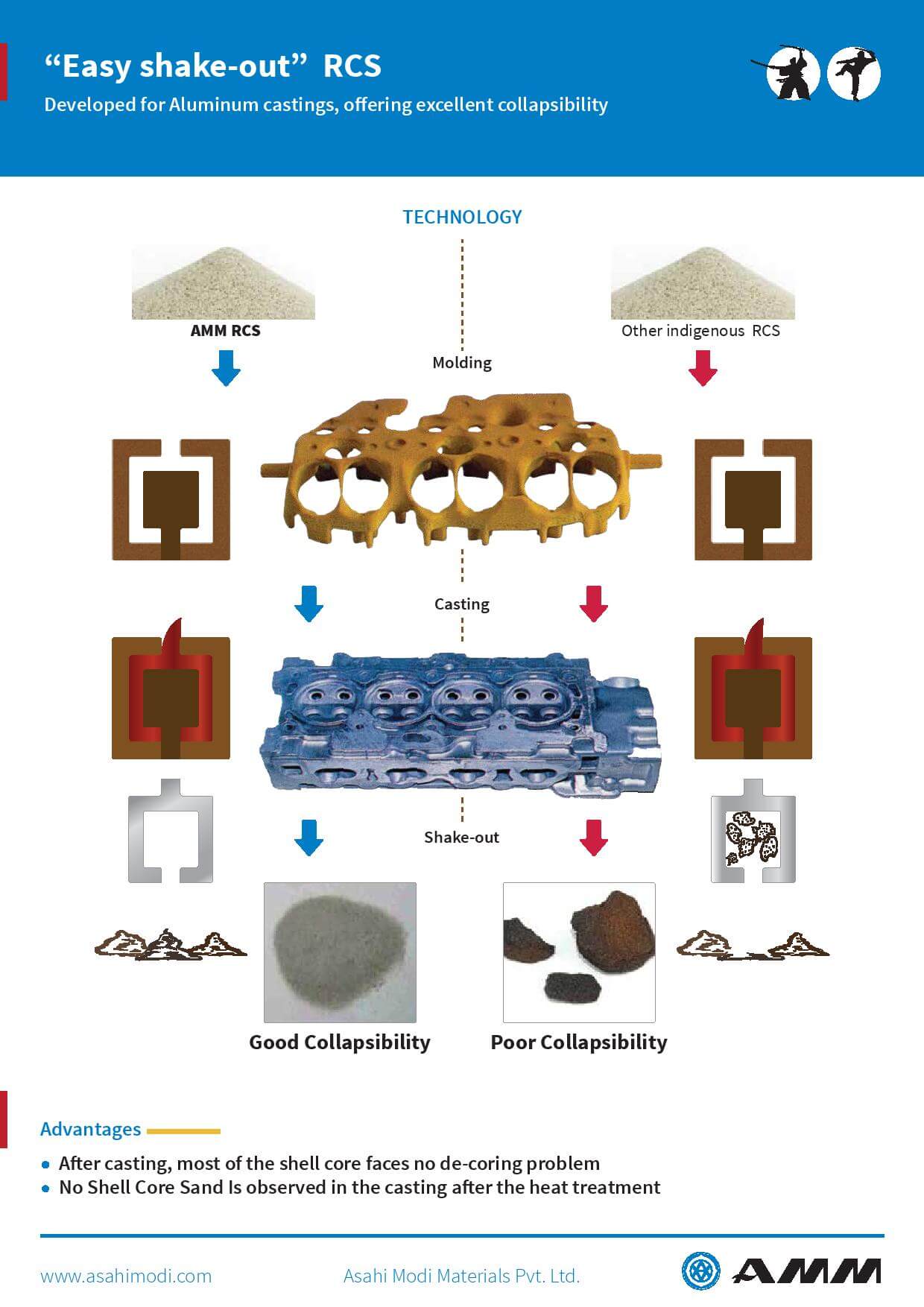

- Collapsibility or shake-out at the time of decoring

- Strength and many more

We tailor-make Resin Coated Sand solutions that address their problems. From diagnosing the issue at hand, to coming up with the best possible remedy, we at AMM are experts in our field and take great pride in saying so.

Speaking of customisation & personalisation, AMM has a USP of successfully developing and customizing resin-coated sand offerings to meet the requirements of its customers. Given the fact that AYC has been operating in the industry of Resin Coated Sand in Japan, for the last 60 years and hence has managed to make more than 700 Resin Coated Sand formulations, thereby catering to the need of each & every casting.

Due to the usage of solid phenolic resins and high quality washed silica sand, we are able to achieve better flow, lesser curing time and better strength. This results in fewer rejections. Moreover, surface coating of molds/cores can be eliminated and is proven to be cost-efficient as it helps in eliminating costs associated with coating, baking and lowered rejection rate, and hence lowers the cost of production for users. Therefore, users get a better output.